The Role of electrodes in Magnetic Flowmeters

Published on 01 09, 2025 in Category: GENERAL

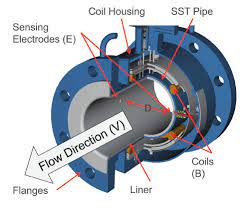

Magnetic flowmeters are widely used in industrial applications to measure the flow of conductive fluids with precision. At the core of the flowmeter sensor operation are the electrodes which are vital to capturing accurate flow data. Keco Engineered Controls, a trusted provider of high quality flow measurement solutions provides the Rosemount Magnetic Flowmeter which includes advanced flow electrode technology to ensure exceptional flow measurement performance.

But how exactly do the electrodes contribute to that performance?

Electrode Placement and Purpose

In a magnetic flowmeter, electrodes are carefully placed inside the sensor tube where the fluid flows. As the conductive liquid passes through a magnetic field generated by a coil in the sensor it creates an electric voltage. This voltage is proportional to the velocity of the fluid flowing through the sensor. The electrodes are the contact points that detect this voltage.

Positioned opposite each other, the electrodes measure the induced voltage across the fluid which is then transmitted to a flow converter. The Rosemount Magnetic Flowmeter uses precisely designed and manufactured electrodes to insure accurate voltage measurements.

Electrode Material

The material of the electrodes is an important choice because they are in contact with the process fluid. They must be manufactured using materials that can withstand the characteristics of the fluid being measured. For example, if the fluid is corrosive, electrode materials such as stainless steel or Tantalum may be used to ensure durability because of their resistance to chemical corrosion. The Rosemount Magnetic Flowmeter provides a number of electrode material options to ensure long life with the fluids the meter is designed to measure.

Accuracy and Reliability

The electrodes play a significant role in the accuracy and reliability of a magnetic flowmeter. Any interference in the electrode performance can lead to inaccurate measurements. The potential buildup of particulate or chemical coating on the electrodes is an important consideration in the design of the meter. Fortunately the meter diagnostics combined with the Calibration Verification feature provide a measurement of the electrode resistance and sensor coil resistance and inductance over time. An analysis of these results can be used to determine if no maintenance is needed, or if meter cleaning or parts may be needed in the future to maintain meter accuracy and reliability.

Self-Cleaning and Maintenance

Rosemount Magnetic Flowmeters are designed with self-cleaning electrode features along with the diagnostic features to provide a meter with a long lifespan requiring minimal maintenance. The original design and configuration are the key to achieving these results. Keco Engineered Controls uses its many years of design, configuration, and Calibration Verification experience to select the best meter for your application. Please email us at sales@kecocontrols.com, call us at 732 901-5900, or request information or a quote using our contact form. We look forward to hearing from you!